3D Printing FibreTuff, Amphiphilic Prototype Implants

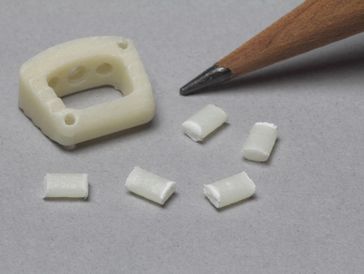

Cervical Spacer printed with FibreTuff

X-Ray and CT Scans of 3D Printed FibreTuff

Eco Friendly Barium Coating for Phantoms

Cervical spacer made by 3D Printing FibreTuff Biocompatible materials. This cervical spacer has been identified under a medical X ray.

Eco Friendly Barium Coating for Phantoms

X-Ray and CT Scans of 3D Printed FibreTuff

Eco Friendly Barium Coating for Phantoms

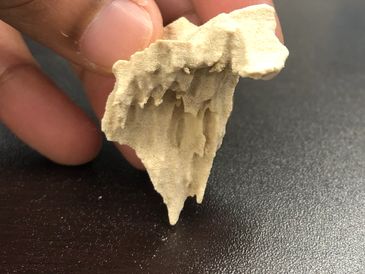

3D Printing a vertebrae made with FibreTuff Biocompatible Materials. The vertebrae is coated with a eco friendly barium solution. The coating provided a bone ring similar to real bone ring developed by Robert Joyce.

X-Ray and CT Scans of 3D Printed FibreTuff

X-Ray and CT Scans of 3D Printed FibreTuff

Bar Stock available in 16mm, 20mm and 30mm dia. for CNC machining

X- Ray and CT scan of a printed calcaneus bone made with FibreTuff Biocompatible Materials. The 3D Printing of PAPC with an eco friendly coating produced a customized phantom. FibreTuff had a bone ring of 3000 HU similar to a real bone ring at 2500 HU.

Bar Stock available in 16mm, 20mm and 30mm dia. for CNC machining

Bar Stock available in 16mm, 20mm and 30mm dia. for CNC machining

Bar Stock available in 16mm, 20mm and 30mm dia. for CNC machining

The FibreTuff medical grade biocompatible materials is used to manufacture bone scaffolds and implant prototypes such as TLIF, Spine cages. For 3D printing bar stock contact robert@fibretuff.us

3D Printing FibreTuff having surface porosity

Bar Stock available in 16mm, 20mm and 30mm dia. for CNC machining

3D Printing FibreTuff having surface porosity

The 3D Printing of FibreTuff Biocompatible materials shows no harm to living tissue or cells. The FibreTuff PAPC has been printed to produce bone scaffolds tested by Universities, medical centers showing conductive properties without coatings.

Hydroxyapatite coated FibreTuff PAPC

Bar Stock available in 16mm, 20mm and 30mm dia. for CNC machining

3D Printing FibreTuff having surface porosity

FibreTuff has exceptional 3D printing attributes for coating bone scaffolds, spine cages. The printed amphiphillic FibreTuff is coated with Hydroxyapatite.

3D Printed FibreTuff Metatarsal With Cortex Screw

This 3D printing of the FibreTuff PAPC biocompatible material, which is a type of biocompatible 3D printer filament, produced the cranial flap shown above. The high-resolution 3D printed cranial flap, made from this innovative tuff material, took 90 minutes to produce.

3D Printed FibreTuff PAPC

3D Printing Conformal Circuits on FibreTuff

FibreTuff PAPC is the first bone like 3D printing product with biocompatible ingredients to utilize printed circuits. nScrypt has demonstrated this unique technology which can be applied to CMF for cases where vestibular issues may exist.

3D Printed FibreTuff PAPC has Bone Like Behavior with Absorbent Features

The 3D Printing FibreTuff PAPC is the best biocompatible material to replace bone like behavior. The printed PAPC once exposed to fluids becomes more flexible with improved impact.

Radiographic Image of a 3D Printed Femur Bone without Traditional Radio pacifiers

Radiographic Image of a 3D Printed Femur Bone without Traditional Radio pacifiers

The 3D Printing of FibreTuff PAPC - Polyamide, Polyolefin and Cellulose, an advanced nylon alloy composite has bone like performance including radiopacity. The 3D Printed Biocompatible PAPC radiographic image - CT Scans, Xray and Ultrasound can be -200HU to 200HU, less or equal to the attenuation of real bone. Not radiopaque or radiolucent.

3D Printed FibreTuff PAPC conforms to RSNA standards

3D Printed Dentistry Opportunities Utilizing pores with micro construction

Radiographic Image of a 3D Printed Femur Bone without Traditional Radio pacifiers

A Dr Hartman, cranio maxillofacial surgeon at Hartman Oral and Maxillofacial Surgery, P.C. has 3D printed FibreTuff medical grade filament. He produced bone scaffolds, anatomical bone like models for CT scans.His work confirms 3D printing FibreTuff PAPC meets the standards set by the Radiological Society of North America (RSNA) per the November 2018 published paper

3D Printed Medical Grade Filament for Cranio Maxillofacial Applications

3D Printed Dentistry Opportunities Utilizing pores with micro construction

3D Printed Dentistry Opportunities Utilizing pores with micro construction

A Dr Cafino in the Philippines worked with FibreTuff customer service for a couple hours to get the appropriate print settings to produce this temporal bone. The printed temporal bone made with FibreTuff filament. After 3D printing a successful temporal bone model for pre surgical planning he drilled into the model at 20,000 RPM for simul

A Dr Cafino in the Philippines worked with FibreTuff customer service for a couple hours to get the appropriate print settings to produce this temporal bone. The printed temporal bone made with FibreTuff filament. After 3D printing a successful temporal bone model for pre surgical planning he drilled into the model at 20,000 RPM for simulation. His goals were achieved and more. This highly sophisticated print, temporal bone was printed in 3 hrs.

3D Printed Dentistry Opportunities Utilizing pores with micro construction

3D Printed Dentistry Opportunities Utilizing pores with micro construction

3D Printed Dentistry Opportunities Utilizing pores with micro construction

FibreTuff Biocompatible PAPC filament has been 3D printed in a cellular structure even a bone scaffold. The scaffold has been exposed to simulated body fluids without pore closure. Possible opportunities and collaboration for 3D Printing regenerative tissues. Write robert@fibretuff.us for more information.

3D Printing Medical Solutions with FibreTuff Biocompatible Materials for Point of Care

This 3D printed foot bone is produced from FibreTuff PAPC powders. The printed foot bone is biocompatible, a amphiphilic material promoting bone likeness with superior strength to weight ratio and a dense cellular structure for excellent screw retention.

3D Printing Project Information and Services

3D Print.Com publishes article about FibreTuff

3D Print.Com publishes article about FibreTuff

3D Print.Com publishes article about FibreTuff

3D Printing FibreTuff Medical Models Are Bone-Like & Anatomically Correct May 20, 2020 by Bridget O'Neal

3D printed bone scaffolds modeling research

3D Print.Com publishes article about FibreTuff

3D Print.Com publishes article about FibreTuff

3D Printing / Fabrication of Bone Scaffolds, Based on FibreTuff

Research Group:

Dr. Ross Salary, Division of Engineering, Marshall University, Huntington, WV, 25504

3D Printing FibreTuff PAPC Biocompatible Materials & Products

Cookie Policy

This website uses cookies. By continuing to use this site you accept our use of cookies.