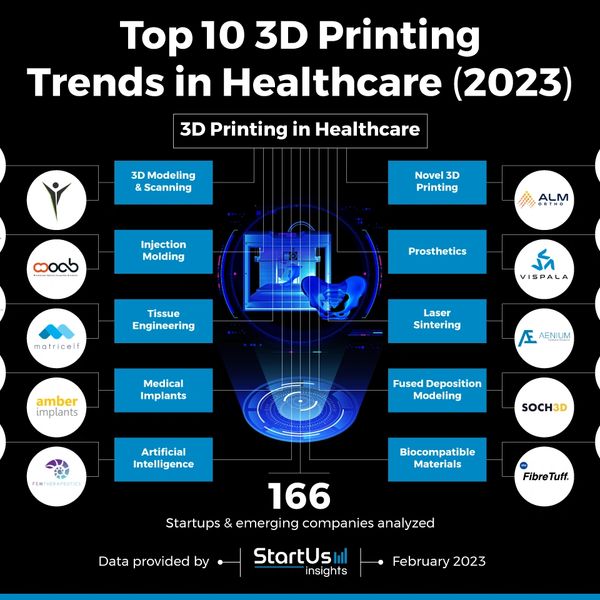

3D Printing Awards For 3D Printed FibreTuff PAPC

Awarded Winning FibreTuff Selected as Top 10 3D Printing Healthcare Start up

FibreTuff was born out of a passion for light weighting with natural fiber composites. The 3D printing of composites by Robert Joyce evolved into amphiphilic biomaterials with superior bone likeness. The company continues to advance the FibreTuff technology creating new devices and implantable's.

3D Printed Bone Likeness, Amphiphilic Parts With FibreTuff

FibreTuff has Bone like Radiopacity

3D printing of FibreTuff has "bone like" feel and appearance with radiopacity. The printed FibreTuff biocompatible material had radiopacity and can show a bone ring seen in the CT . An independent study performed by 3D LifePrint evaluated and compared other materials they have used for anatomical bone models. 3D LifePrint found FibreTuff to be more bone like ( HU 400 ) than any other materials presently printed today in the medical market.

FibreTuff will absorb moisture to increase flexibility and impact

The best material to replace bone is printed FibreTuff PAPC. This amphiphilic material is similar to real bone. FibreTuff PAPC has brittleness once fluids are removed. The 3D Printed PAPC has absorbency with a porous and non porous surface. Furthermore, the printed PAPC biocompatible materials will absorb moisture to a point, eventually wicking moisture away. Other 3D printing medical biomaterials like PLA will absorb and store moisture until the composition breaks down or degrades.

3D Printing FDM+SLS+Bioprints

3D Printed Cranio Maxillofacial Bones with FibreTuff

IMECE 2023 debuts 3D Printed Scaffolds with FibreTuff PAPC Technology

BioPrinting with FibreTuff Porous Cellular Structure and Collagen

3D Printing FibreTuff biocompatible material can produce bone like skull caps for functional models used by medical centers and physicians.

BioPrinting with FibreTuff Porous Cellular Structure and Collagen

IMECE 2023 debuts 3D Printed Scaffolds with FibreTuff PAPC Technology

BioPrinting with FibreTuff Porous Cellular Structure and Collagen

3D Printing Bio fabricated parts manufactured with the FibreTuff medical grade biocompatible material showed collagen adhesion. The prototype symmetrical pore structure at 200 micron helps to create biocompatible amphiphilic bone like implants.

IMECE 2023 debuts 3D Printed Scaffolds with FibreTuff PAPC Technology

IMECE 2023 debuts 3D Printed Scaffolds with FibreTuff PAPC Technology

IMECE 2023 debuts 3D Printed Scaffolds with FibreTuff PAPC Technology

The FibreTuff PAPC+Nylon66 has ingredients that are synergistic. The 3D Printing of the FibreTuff PAPC biocompatible material could possibly provide implants that are non re sorbable with evidence based healing.

3D Printed FibreTuff has been identified in ultrasound images

3D Printed FibreTuff has been identified in ultrasound images

IMECE 2023 debuts 3D Printed Scaffolds with FibreTuff PAPC Technology

3D Printing of FibreTuff PAPC medical grade biocompatible materials has been identified in Ultrasound images. The 3D printed PAPC could show thickness of a cranio maxillofacial bone for evidence based healing.

3D Printed FibreTuff has exceptional machining ability

3D Printed FibreTuff has been identified in ultrasound images

3D Printed FibreTuff has exceptional machining ability

The 3D printing of FibreTuff PAPC biocompatible material can produce bar stock for machining spine implant prototypes and surgical guides.

3D Printed Cranial Flap with FibreTuff

3D Printed FibreTuff has been identified in ultrasound images

3D Printed FibreTuff has exceptional machining ability

This 3D Printing of the FibreTuff PAPC biocompatible material produced the cranial flap shown above. The 3D printed cranial flap took 90 minutes to produce and has high resolution .

Radiographic Image of 3D Printed FibreTuff

Femur Bone made with FibreTuff

Femur Bone made with FibreTuff

Femur Bone made with FibreTuff

CT Scan of Femur Bone

Femur Bone made with FibreTuff

Femur Bone made with FibreTuff

Spinal Cage made with FibreTuff

Femur Bone made with FibreTuff

Spinal Cage made with FibreTuff

CT Scan of Spinal Cage

Ultrasound of 3D Printed Cranial Flap made with FibreTuff

Spinal Cage made with FibreTuff

XRay and CT Scan Calcaneus Bone

Ultrasound of 3D Printed Cranial Flap made with FibreTuff

Ultrasound of 3D Printed Cranial Flap made with FibreTuff

Ultrasound of 3D Printed Cranial Flap made with FibreTuff

Ultrasound of 3D Printed Cranial Flap made with FibreTuff

Ultrasound of 3D Printed Cranial Flap made with FibreTuff

3D Printing FibreTuff PAPC a biocompatible material

This 3D printing of the cranio maxillofacial bone was made using FibreTuff PAPC biocompatible materials, showcasing a thickness of 9 mm. A paper clip was inserted to simulate a metal staple, and upon removal, the image was altered to replicate the actual procedure, demonstrating the effectiveness of biocompatible 3D printer filament in medical applications.

Cookie Policy

This website uses cookies. By continuing to use this site you accept our use of cookies.